Unfortunately those of us who do know history get dragged right along with the others, because we live in a world where everything is connected to everything else.

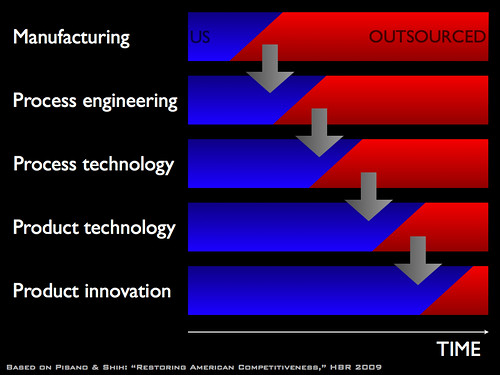

Above is my visualization of Pisano and Shih's 2009 Harvard Business Review article "Restoring American Competitiveness." This is a stylized version of a story that has happened in several industries.

Step 1: Companies start outsourcing their manufacturing operations to companies (or countries) which can perform them in a more cost-effective manner. Perhaps these companies/countries have cheaper labor, fewer costly regulations, or less overhead.

Step 2: Isolated from their manufacture, companies lose the skills for process engineering. After all, improving manufacturing processes is a task that depends on continuous experimentation and feedback from the manufacturing process. If the manufacturing process is outsourced, the necessary interaction between manufacturing and process engineers happens progressively more inside the contractor, not the original manufacturer.

Step 3: Without process engineering to motivate it, the original manufacturer (and the companies supporting it in the original country, in the diagram the US) stops investing in process technology development. For example, the companies that developed machine tools for US manufacturers in conjunction with US process engineers now have to so do with Taiwanese engineers in Taiwan, which leads to relocation of these companies and eventually of the skilled professionals.

Step 4: Because of spillovers in technological development between process technologies and product technologies (including the development of an engineering class and engineering support infrastructure), more and more product technology development is outsourced. For example, as fewer engineering jobs are available in the original country, fewer people go to engineering school; the opposite happens in the outsourced-to country, where an engineering class grows. That growth is a spillover that is seldom accounted for.

Step 5: As more and more technology development happens in the outsourced-to country, it captures more and more of the product innovation process, eventually substituting for the innovators in the original manufacturer's country. Part of this innovation may still be under contract with the original manufacturer, but the development of innovation skills in the outsourced-to country means that at some point it will have its own independent manufacturers (who will compete with the original manufacturer).

Pisano and Shih are optimists, as their article proposes solutions to slow, stop, and reverse this process of technological decline of the West (in their case, the US). It's worth a read (it's not free but it's cheaper than a day worth of lattes, m'kay?) and ends in an upbeat note.

I'm less optimistic than Pisano and Shih. Behold:

Problem 1: Too many people and too much effort dedicated to non-wealth-creating activities and too many people and too much effort aimed at stopping wealth-creating activities.

Problem 2: Lack of emphasis in useful skills (particularly STEM, entrepreneurship, and "maker" culture) in education. Sadly accompanied by a sense of entitlement and self-confidence which is inversely proportional to the actual skills.

Problem 3: Too much public discourse (politicians of both parties, news media, entertainment) which vilifies the creation of wealth and applauds the forcible redistribution of whatever wealth is created.

Problem 4: A generalized confusion between wealth and pieces of fancy green paper with pictures of dead presidents (or Ben Franklin) on them.

Problem 5: A lack of priorities or perspective beyond the immediate sectorial interests.

We are doomed!